Expert Mold Design: Houston’s Services

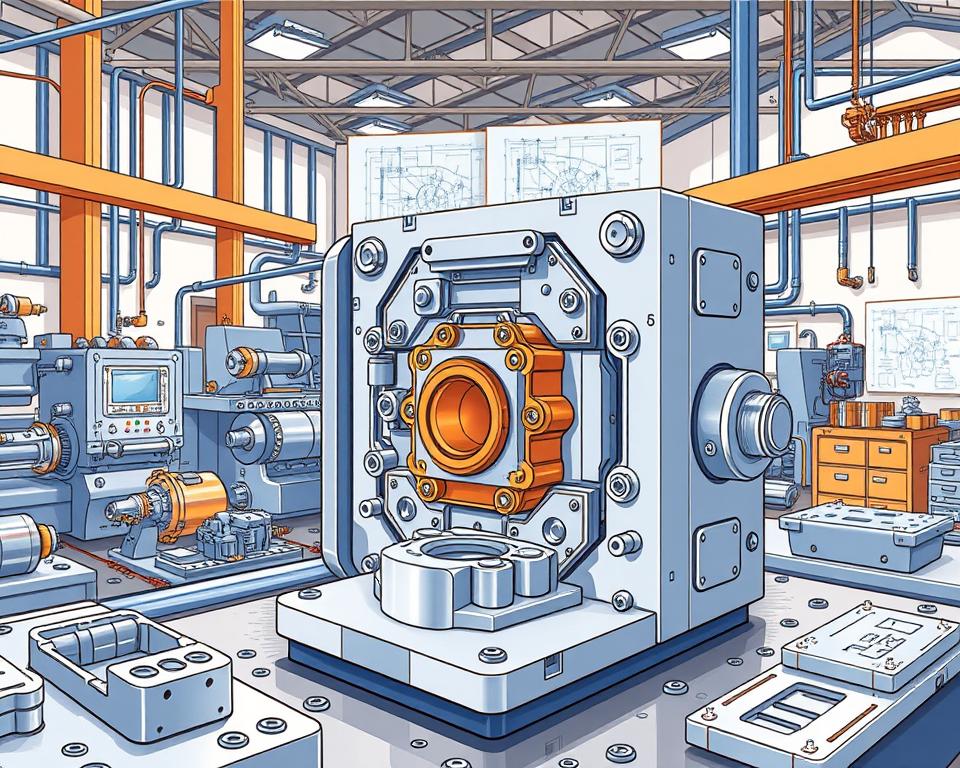

The global injection molded plastics market is set to hit $440 billion by 2025. These figures emphasize the critical role of professional mold design. They deliver bespoke, top-tier mold designs across multiple sectors. Among Houston companies, Lowrance Machine is renowned for mold design. They provide cutting-edge mold solutions for the automotive, aerospace, and consumer-goods markets.

Leveraging CAD platforms and 3D-printing technology, Lowrance Machine. Their team ensures precision and efficiency in the molding process. With their extensive experience and technical skills, they are a reliable partner for businesses. Explore how their injection molds Houston services can improve your projects and meet today’s market demands.

Why Mold Design Services Matter

In manufacturing, mold design services directly influence quality and process efficiency. Mold design dictates product performance and durability. Investing in skilled mold design can slash costs and improve quality benchmarks.

Lowrance Machine demonstrates why veteran experts matter. They collaborate intimately with customers to engineer bespoke molds. Through CAD-driven 3D modeling, they produce molds of exceptional standard.

Selecting expert mold design partners enhances product output and propels company performance. Streamlined mold design fosters efficient production and sharpens competitive stance.

Available Mold Design Services in Houston

Houston’s Lowrance Machine provides diverse mold design services customized for each sector. Familiarity with service categories ensures companies pick the right mold solution. Key categories include:

- Custom Design Solutions: Tailored mold designs crafted to precise specs.

- Test Mold Creation: Early-stage mold prototyping to validate designs.

- Injection Molds Houston: High-quality injection molds designed for durability and precision, ideal for various manufacturing applications.

- Advanced 3D Design: Advanced CAD to develop exact 3D mold prototypes.

- Repair and Maintenance: Repair and upkeep solutions to maximize mold longevity.

Each service is designed to streamline production, improve product quality, and ensure cost-efficiency. Knowing the service spectrum lets companies tailor mold design to their operational objectives.

Why Hire Professional Mold Designers

Partnering with seasoned mold designers yields multiple manufacturing benefits. Gain improved accuracy, robustness, and throughput. Tailored molds ensure top-notch quality and repeatable outcomes.

Experienced mold design experts offer insights that streamline production. They align molds with regulatory and bespoke requirements. Joint efforts spark innovation and extend product longevity.

Economical operations are a key perk. Cutting-edge methods slash material waste and speed up delivery. This results in substantial savings, boosting a manufacturing operation’s financial health. Swift design workflows speed time-to-market, sharpening competitive positioning.

Overall, professional mold services underpin manufacturing success. They aim to optimize production capabilities and enhance product offerings.

Cutting-Edge Mold Design Methods

Technological progress has revolutionized mold design. Lowrance Machine leads the way with its cutting-edge mold design techniques. These methods enhance throughput and refine product excellence. Advanced mold design technologies play a significant role, streamlining the creation of unique molds and cutting down on time and costs.

3D printing is a standout among these techniques, enabling quick prototyping and complex designs. It slashes raw-material loss relative to traditional processes. Simulation platforms enable virtual mold testing and enhancement for superior performance and throughput.

Locally, mold designers in Houston leverage these advanced practices. Companies are gaining a competitive advantage by leveraging digital design tools and advanced fabrication methods. They facilitate flexible, rapid-response mold development to satisfy diverse applications.

| Technique | Description | Benefits |

|---|---|---|

| Additive Manufacturing | Utilizes additive manufacturing to create molds rapidly. | Shortens delivery times and cuts scrap. |

| Virtual Testing Tools | Offers virtual mold performance simulations. | Enhances accuracy and optimizes performance. |

| CAD Platforms | Integrates advanced software for precise mold specifications. | Enables tailored designs and quick edits. |

Final Thoughts

Professional mold design underpins both efficient operations and quality products in Houston. They provide the technical skill needed for complex mold projects. They ensure that each company’s unique needs are met, leading to better outcomes.

Renowned for precision and teamwork, Lowrance Machine leads the mold design field. The benefits of mold design, such as customized solutions and cutting-edge technologies, help manufacturers stay ahead in a fast-changing market. Working with mold design experts improves product quality and streamlines operations.

Opting for professional mold design in Houston balances high standards with operational efficiency. Companies will satisfy market demands and sharpen their competitive edge. Adopting these specialized services is vital for manufacturers aiming to succeed in today’s competitive environment.